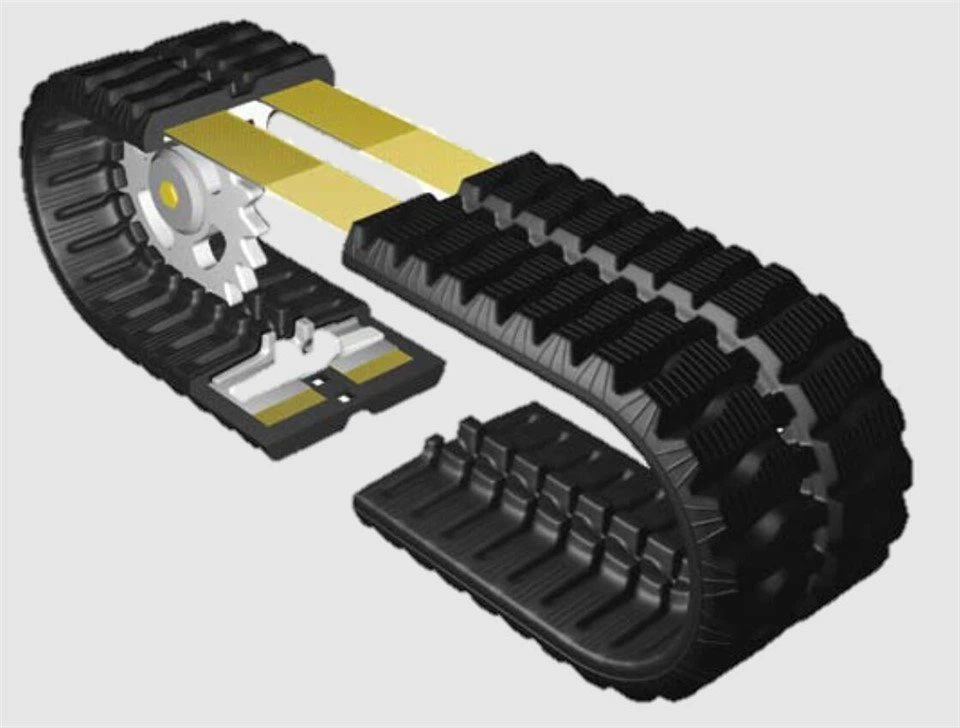

Engineering Rubber Track

RoyalCorp engineering Rubber Tracks are built to match the precise needs and demands of your compact equipment. High-quality Genuine RoyalCorp parts are specifically manufactured and tested to ensure your compact equipment continues to operate at peak performance. Don’t trust just any track supplier to provide such a critical component of your undercarriage system. Rely on Genuine RoyalCorp Rubber Tracks to deliver the performance and durability you need – where you need it.

ATTENTION

1- Check the tension after the track belt installed, it will be failure if too tight or loose. Generally, the sag distance of the center roller is 10 to 15cm to belt when lift the machine.

2- Avoid quickly starting or turning the machine on the scraggly ground.

3- Keep the rubber away from oil and grease, wipe off immediately while it is oil stained.

4- To avoid collision between the rubber track and other components of the machine, especially its inner edge.

5- Don't using badly worn driving wheel, because it may damage the iron teeth of the rubber track.

6- If the machine is unused for a long time, the rubber track should be removed and cleaned, and kept well indoors to avoid sunlight and wetness.

7- Due to the track belt was made by rubber, the perfect working temperature is between -25 to 55 degree. However, it can meet the needs out of the range if made by special rubber and material.

Hot Tags: engineering rubber track, China, suppliers, manufacturers, factory, customized, wholesale, buy, low price, for sale, Rubber Track for Snowmobile, Engineering Rubber Track, Agricultural Rubber Track

Send Inquiry